Preferred Choices and Utilization Trends in Industrial Motor Selection

==========================================================================================

Industry professionals are faced with a multitude of factors when selecting the ideal motor for their specific applications. A recent guide, based on survey data from both integrators and end-users in the industry, provides practical knowledge on the factors influencing motor selection.

The guide covers four main motor types: AC induction, synchronous, DC, and servo motors. The choice between these options is not a simple one, as it hinges on multiple real-world factors that prioritize performance characteristics such as torque, variable frequency drive (VFD) compatibility, cost, energy efficiency, and best fit for the application’s operational requirements.

Torque and Speed Profiles

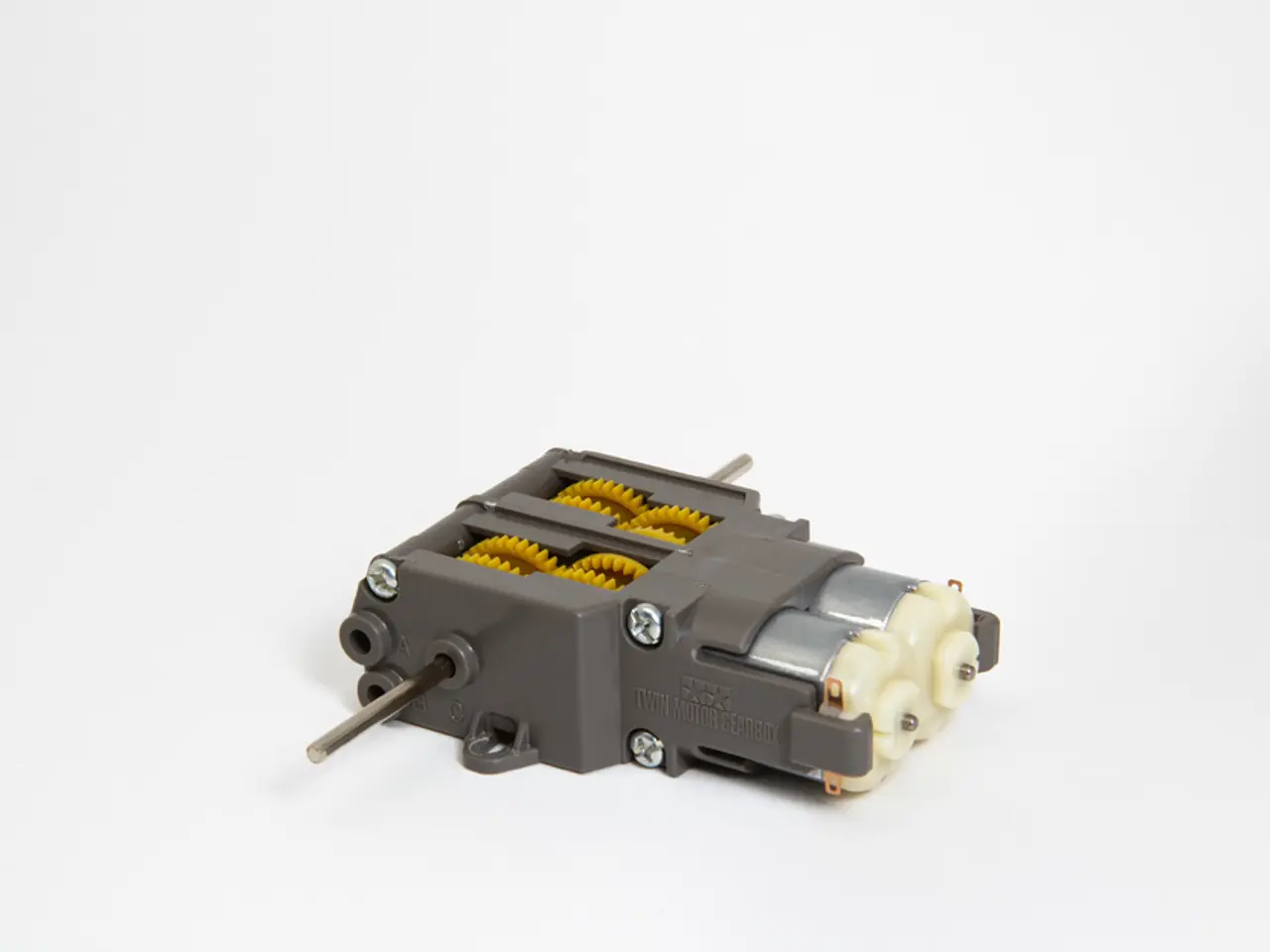

The required torque and speed range are primary considerations. Servo motors are favored for applications requiring high torque and speed control, especially at speeds above 1,000 RPM, where they maintain torque effectively. Stepper motors, by contrast, excel at moderate speeds under 1,000 RPM with consistent torque and holding capability, suitable for predictable load scenarios. High torque gear motors require matching torque and speed to the application, highlighting the importance of precise load assessment.

VFD Compatibility and Control Complexity

AC induction and synchronous motors are commonly used with variable frequency drives (VFDs) for variable speed operation, which enhances energy efficiency by matching motor speed to load demands. Servo motors offer advanced control through real-time feedback, enabling high precision, repeatability, and coordination across multiple axes—essential for robotics and CNC applications. This integration capability supports system compatibility and scalability.

Cost Considerations

Total cost of ownership, including initial purchase price and ongoing energy and maintenance costs, heavily influences motor choice. Stepper motors typically cost 20-30% less than servo motors and are preferred where budget constraints exist and load conditions are stable. However, servo motors’ higher upfront cost is often justified by gains in efficiency, quality, throughput, and lower maintenance needs over time. Brands with quality reputations also impact lifecycle costs through reliability and availability of parts.

Energy Efficiency and Maintenance

Energy savings potential is significant, especially with servo motors that incorporate variable speed drives, regenerative braking, and optimized control algorithms that reduce power consumption. Brushless designs and sealed components reduce wear and maintenance frequency in servo and advanced AC motors, contributing to lower operating costs and downtime.

Application Fit and Performance Requirements

Matching motor type to specific application needs—including load variability, precision, speed consistency, duty cycle, and environmental conditions—is critical. For example, servo motors are preferred for tasks requiring precision under variable loads and multi-axis coordination, such as assembly and machining. In contrast, AC induction motors remain a cost-effective choice for consistent load industrial applications where precision is less critical.

Market and Industry Knowledge

Industry professionals must also consider market dynamics, technical performance standards, and lifecycle characteristics to select or recommend the optimal motor. Automotive OEMs expanding into industrial motor markets face challenges translating their high-speed motor expertise to meet diverse industrial requirements related to design life, operating conditions, and speed ranges.

In conclusion, the selection of industrial motors balances performance priorities—torque, speed, efficiency, control complexity—with cost and reliability considerations tailored to each industrial use case. Experts advocate defining detailed technical requirements and consulting suppliers to ensure alignment with operational demands and future scalability. This guide offers valuable takeaways for upgrading existing systems or designing new ones, rooted in real applications, not just theory.

- In the realm of business and finance, the decision to invest in a specific motor for an industrial application also involves technology considerations, such as torque, speed, VFD compatibility, cost, energy efficiency, and application fit.

- The industry of motor selection is not confined to engineering and manufacturing alone; financial and business analysts also need to comprehend market dynamics, technical performance standards, and lifecycle characteristics as they allocate resources for new motor investments.