Is the Reliability of Artificial Intelligence Guaranteed throughout a Product's Lifespan a Concern?

In the rapidly evolving world of manufacturing, Bosch Rexroth is leading the charge by integrating Artificial Intelligence (AI) into their processes. This strategic move aims to enhance process automation, predictive maintenance, quality control, and energy management.

The cornerstone of Bosch Rexroth's AI integration lies in implementing AI-driven systems that enable machines to make intelligent, real-time decisions. These systems optimize production lines and improve human-robot collaboration, leading to reduced downtime and increased productivity.

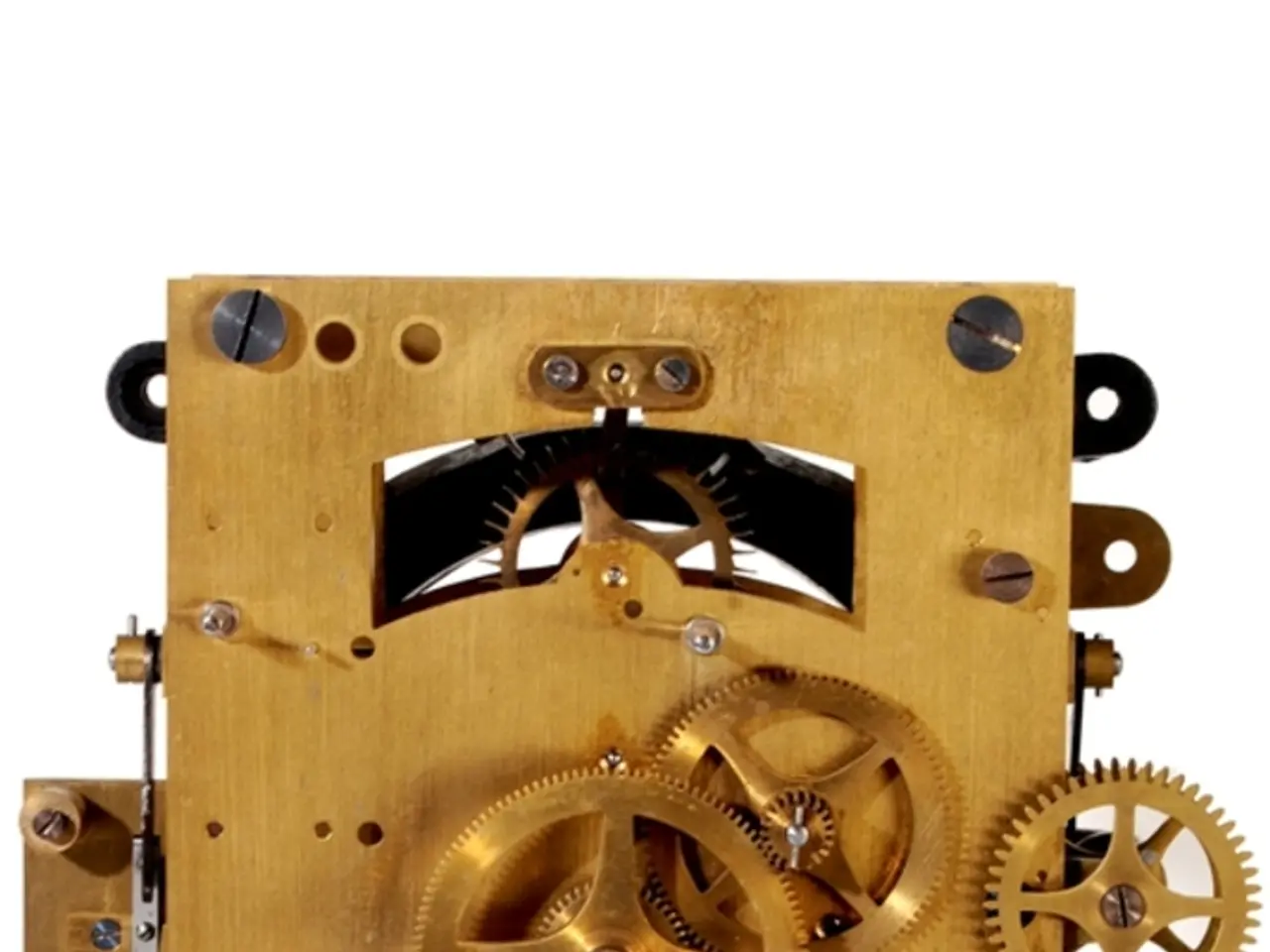

The control system in a manufacturing setup acts as a bridge between AI insights and the physical world, ensuring safe, efficient, and reliable execution of AI recommendations. Traditional automation, which relies on pre-programmed functions and fixed algorithms, is replaced by AI, empowering machines to make intelligent decisions based on real-time data, adapting to changing conditions, and optimizing their performance.

Bosch Rexroth's approach to AI integration requires a phased strategy, focusing on clear objectives, addressing potential challenges, and maximizing data collection. The benefits are substantial: predictive maintenance to foresee equipment failures, zero-defect production through early anomaly detection, substantial reductions in manufacturing costs, improved energy efficiency contributing to carbon neutrality, enhanced quality control via AI-based inspection systems, and scalable automation solutions adaptable across various industries such as packaging, automotive, and consumer goods.

However, the integration of AI into manufacturing isn't without its challenges. Security vulnerabilities and data privacy are risks associated with AI adoption. Researchers, policymakers, and industry leaders are working on safeguards such as bias detection, false data identification, and privacy preservation. Safety and security should be prioritized during the integration of AI into the manufacturing process.

Garrett Wagg, the ctrlX AUTOMATION Product Manager - Automation & Electrification for Bosch Rexroth, spearheads this transformation. The AI module communicates with a PLC device like the Bosch Rexroth ctrlX CORE, a safety controller, and a variety of sensors to close the data exchange loop.

Moreover, the control system based on an open platform enables flexibility and customization in AI capabilities, unlike closed systems. This openness allows fast communication and data exchange with other systems, a benefit of open platform control systems.

In summary, Bosch Rexroth’s AI integration in manufacturing combines cutting-edge AI technologies with industrial expertise to drive efficiency, sustainability, and quality improvements while carefully managing technological and human factors for successful adoption.

The integration of AI into Bosch Rexroth's manufacturing processes not only enhances traditional automation but also ventures into the finance industry, offering potential for cost reductions and increased profitability. Furthermore, the technology aspect of AI integration fosters collaborations with other technology leaders in the industry, promoting innovative solutions and a competitive edge.