Information to be disclosed:

In the world of business, the pursuit of expansion is a common goal. With comprehensive solution platforms, this ambition can be achieved in various sectors, and one such example is the field of machine maintenance. Over the past four years, the use of Augmented Reality (AR) in this domain has surged, driven by its ability to simplify complex tasks, enhance workplace safety, and enable real-time monitoring and support.

Krones, a leading company in the beverage and food industry, is already leveraging AR for service support. With Argos, they can access assistance directly at the machine in just a few seconds, making maintenance more efficient and effective.

One potential use case for remote maintenance with AR is the expansion of service agreements to include AR support. This could significantly reduce downtime, a crucial factor in maintaining productivity. Moreover, the reduction of travel costs is another financial advantage of this technology.

The process of remote maintenance with AR is hands-free if required, ensuring technicians can focus on their tasks without distractions. After purchasing the license and installing the application, an intact internet connection is necessary to start.

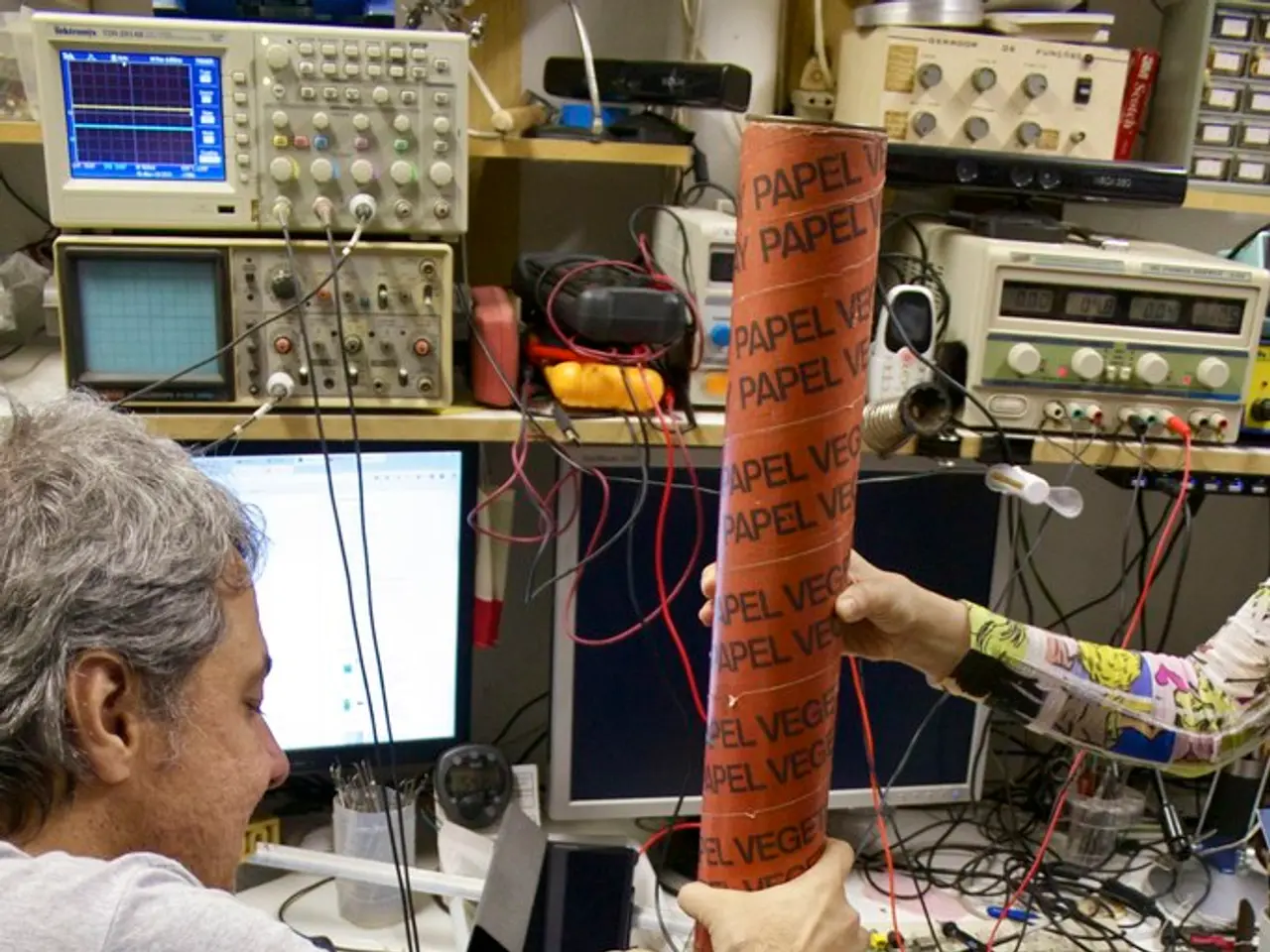

The end device suitable for the process should be determined, with data glasses being a popular choice due to their hands-free nature. These glasses can provide step-by-step work instructions, AR trackers, and colored markings to support technicians during calls. Integration into existing systems can also be beneficial for documentation purposes or media storage.

Digital knowledge transfer is another advantage of remote maintenance with AR. Expert knowledge can be easily shared, minimizing maintenance times and increasing customer satisfaction due to faster service. Medium-term, this approach can also reduce maintenance and service costs and optimize knowledge transfer.

Remote maintenance via Augmented Reality allows experts to analyze and solve problems in real-time without traveling to the location. This not only saves time and resources but also contributes to flexible employee deployment.

The market readiness of the technology is at level 4, indicating a mature stage of development. Long-term, remote maintenance with AR can lead to new service-oriented business models.

However, it's essential to clarify the process to be supported and the requirements for the solution with an experienced solution provider. Real-time fault analysis, avoidance of machine downtime, and improvement of the first-time fix rate are further benefits of using remote maintenance with AR.

In conclusion, the integration of AR in machine and equipment maintenance is revolutionizing the industry, making tasks more manageable, reducing costs, and improving efficiency. As more businesses adopt this technology, we can expect to see even more innovative applications in the future.

Read also:

- Transforming Digital Inventories in the Food Industry: A Comprehensive Guide for Food Businesses

- 1. Key Points for August 14: Gathering in Alaska, Immigration Enforcement (ICE), Financial service Zelle, Infowars, and Air Canada Airline Incidents

- Automobile manufacturer IM Motors reveals an extended-range powertrain akin to installing an internal combustion engine in a Tesla Model Y.

- Conflict Erupts Between Musk and Apple Over Apple Store's Neglect of Grok