Crafting a Stunning 3D Hybrid Clock

Dual-Air Mechanism Timepiece Swings Between Classic and Modern Clockwork Styles

Fancy giving a shot at building your own 3D printed clock? Well, [shiura]'s incredible creation has got us all buzzing! This hybrid clock combines the vintage charm of traditional analog clocks with the digital precision of modern technology, all in a single, eye-catching piece. Let's break it down and see how it's done!

To recreate this beauty, you'll need some savvy in hardware design, firmware, and multi-material 3D printing. Though it might seem complex, we'll outline the steps for you to tackle this exciting project.

Concept Overview- Goal: Combine multi-material printing, a single stepper motor, and an ESP32C6 microcontroller to create a clock- Hybrid Approach: Utilize multi-material printing for intricate components, embed electronics, and use a stepper motor for accurate timekeeping

Let's Dive In!

Step 1: Designing the Clock Mechanism and Enclosure- Use a CAD tool (Fusion 360, TinkerCAD, etc.) to design the clock face, moving parts, and internal mechanism- Consider designing for multi-material printing by using PLA for structural parts and TPU for flexible joints

Step 2: Prepare Your 3D Printer- Ensure your 3D printer supports multi-material printing (multi-extruder setup or tool changer)- Calibrate your printer for each material used (PLA and TPU) to prevent warping and ensure adhesion

Step 3: 3D Print the Components- Print the clock frame, gears, hands, and any flexible couplings- Use PLA for structural parts and TPU for flexible or shock-absorbing components

Step 4: Assembling the Mechanical Parts- Mount the stepper motor and connect it to the clock mechanism- Ensure the stepper can turn the hands or mechanism smoothly, using flexible couplings if needed

Step 5: Integrating Electronics- Utilize a compact, precise stepper motor suitable for clocks (e.g., NEMA 17)- Connect the stepper motor to a compatible driver (e.g., A4988 or DRV8825)- Wire the stepper driver to the ESP32C6 microcontroller for control

Step 6: Develop and Upload Firmware- Write firmware in Arduino/PlatformIO to control the stepper motor for timekeeping- Implement smooth movement to reduce noise and vibration- Add features like time adjustment, alarms, or display modes for customization

Step 7: Power the System- Use a suitable power supply for the stepper motor and ESP32C6

Step 8: Calibration and Testing- Calibrate the stepper motor’s steps per revolution to match the clock's gear ratio- Optimize the stepper motor's acceleration and deceleration curves to reduce vibration and noise

Example Code Snippet

```cpp

// Define stepper motor connections and interfaceAccelStepper stepper(1, 14, 13); // STEP, DIR pins on ESP32C6

void setup() { stepper.setMaxSpeed(500); stepper.setAcceleration(200); WiFi.begin("SSID", "password"); while (WiFi.status() != WL_CONNECTED) delay(500);}

void loop() { // Move stepper to simulate clock hand movement // (Implement time calculation and step logic here) stepper.run();}```

Summary Table

| Component | Description/Model | Purpose/Notes ||----------------------|------------------------------------------|--------------------------------------|| Stepper Motor | NEMA 17 (17HS3401) | Precise movement for clock hands || Microcontroller | ESP32C6 | Control, Wi-Fi/BLE for sync || 3D Printer | Multi-material capable | Print rigid and flexible parts || Materials | PLA, TPU | Structural and flexible components || Driver | A4988, DRV8825 | Stepper motor control |

Key Considerations

- Multi-material Printing: Consider the material compatibility and layer adhesion

- Stepper Motor Selection: Prioritize precision and torque[2]

- Vibration Control: Optimize settings to reduce vibration and noise[1]

- Connectivity: Leverage the ESP32C6's Wi-Fi and BLE capabilities for remote control and time synchronization

Following these steps will allow you to build a functional, stylish, and precise hybrid clock using modern materials and microcontroller technology.

[shiura] was inspired to build this masterpiece after checking out the slideshow clock we'd recently featured. So why not put on your maker hat and join the fun?

[1] - Vibration Control Optimization Strategies

[2] - Stepper Motor Selection Guide

[3] - 3D Printer Calibration Guide

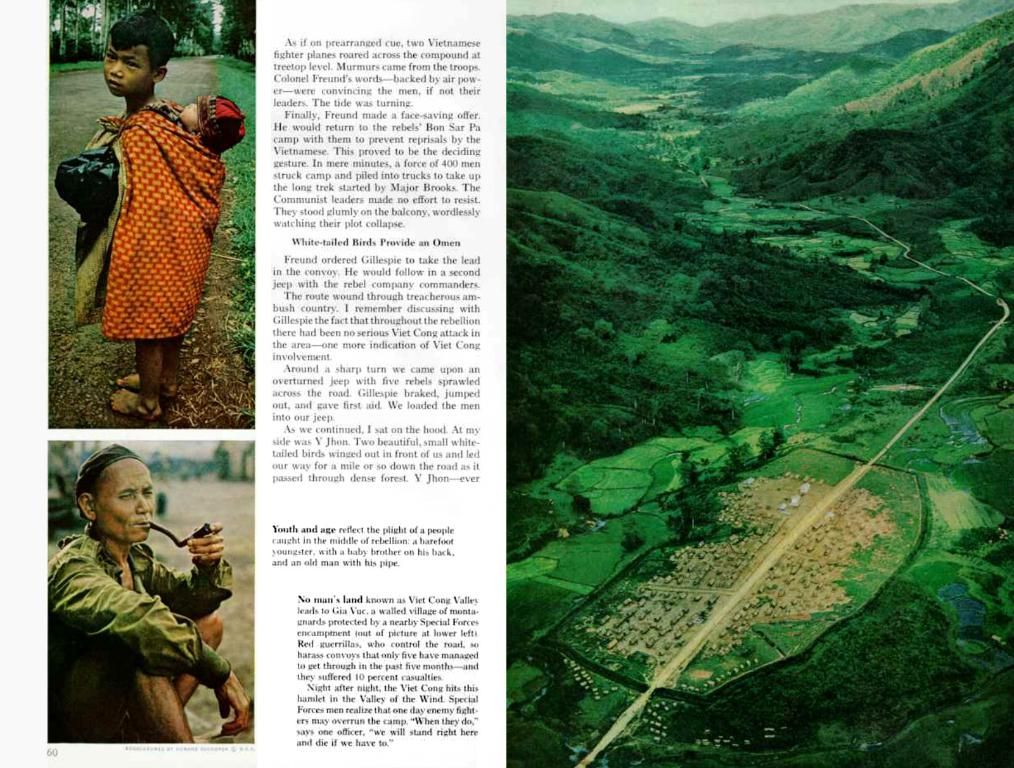

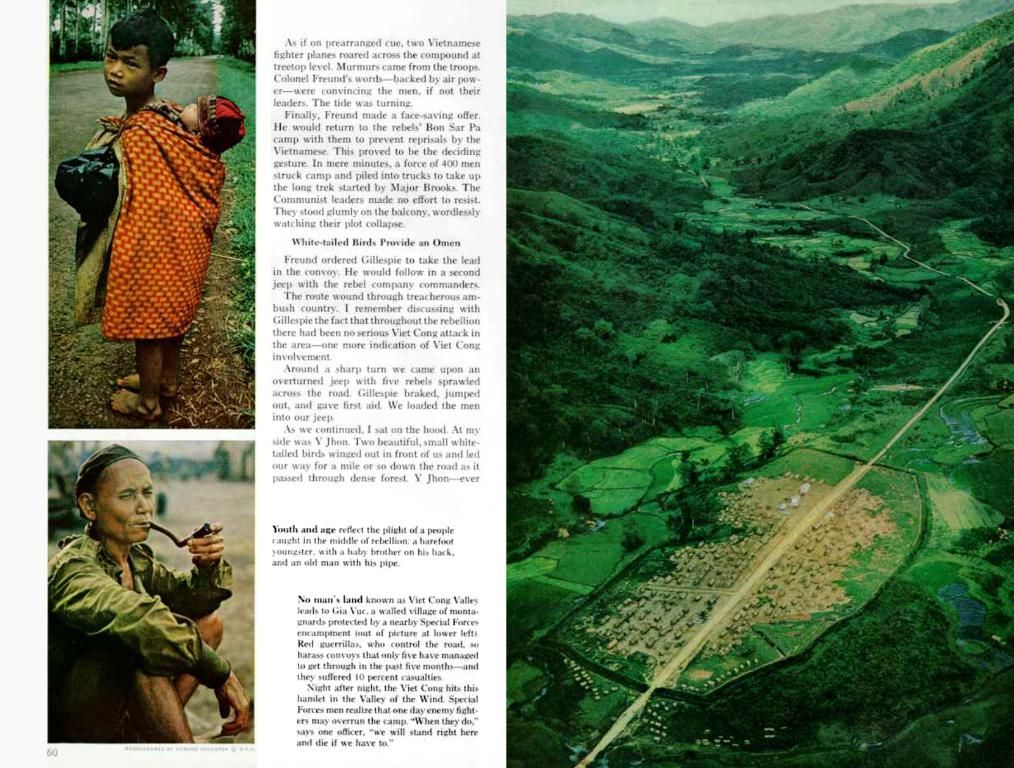

In this intriguing project, you can create a fusion of traditional and modern elements by integrating electronic gadgets into a 3D printed clock. The clock design will utilize multi-material printing to create both structural and flexible components, such as the frame and joints respectively. (Step 3: 3D Print the Components)

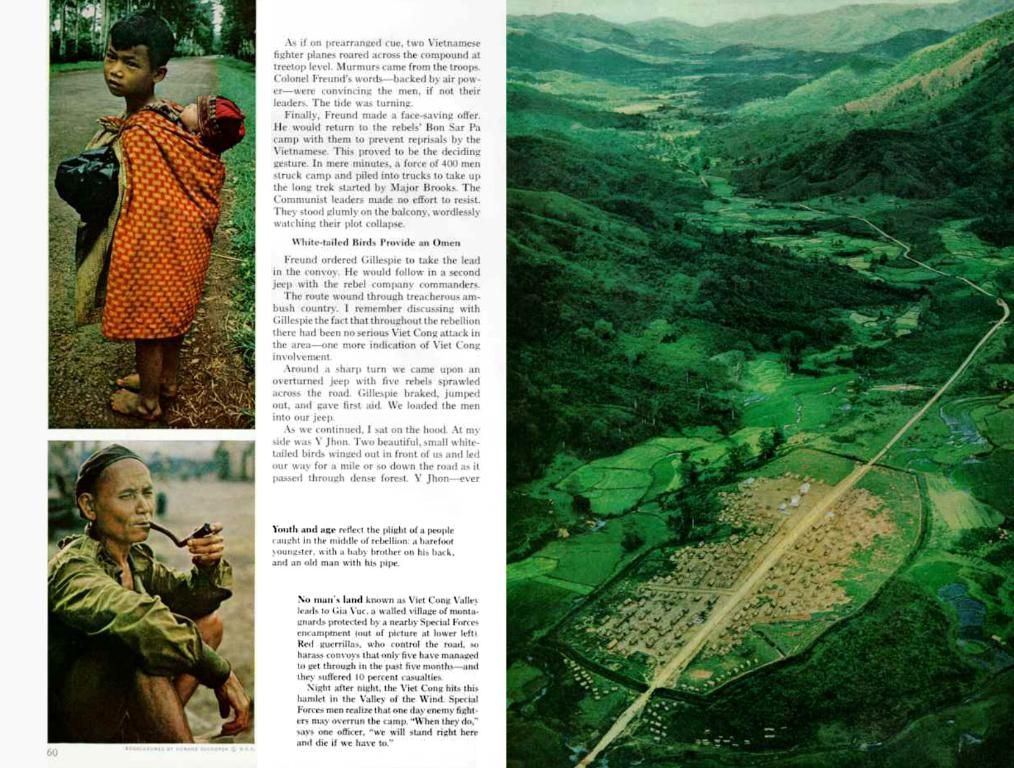

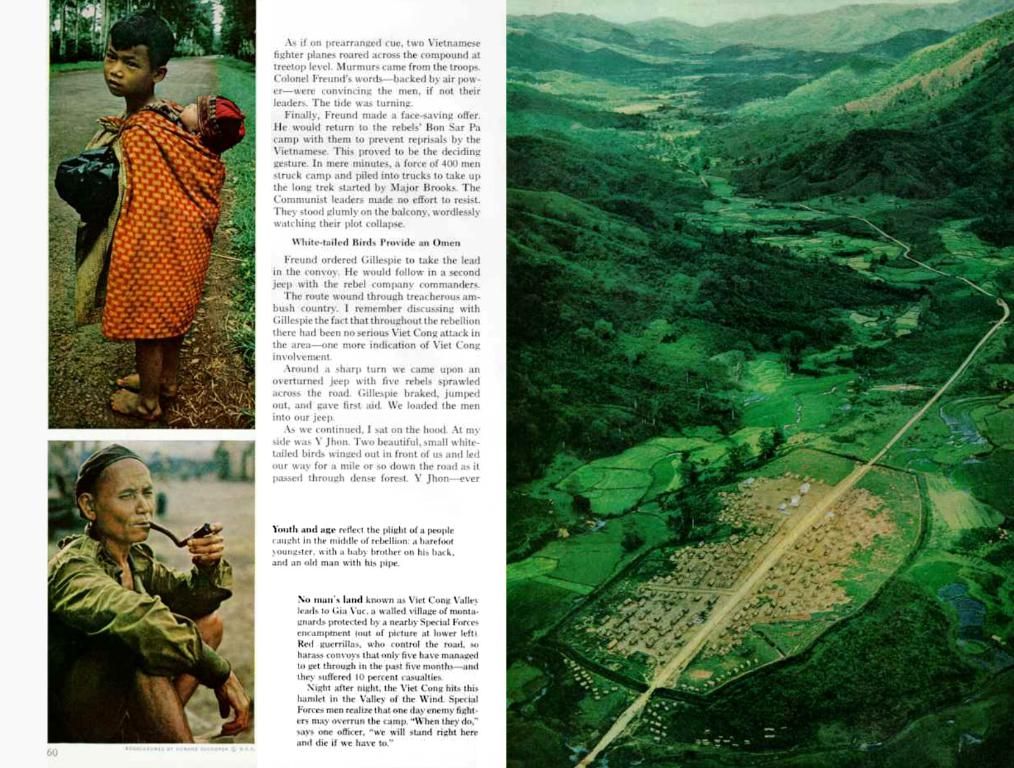

Moreover, to power this high-tech piece, you might need various electronics, such as a compact stepper motor, microcontroller, driver, and suitable power supply. (Step 5: Integrating Electronics)