Desired PCB Router Design You Long for Crafting Yourself

Take a Gander at the PCB Milling Revolution

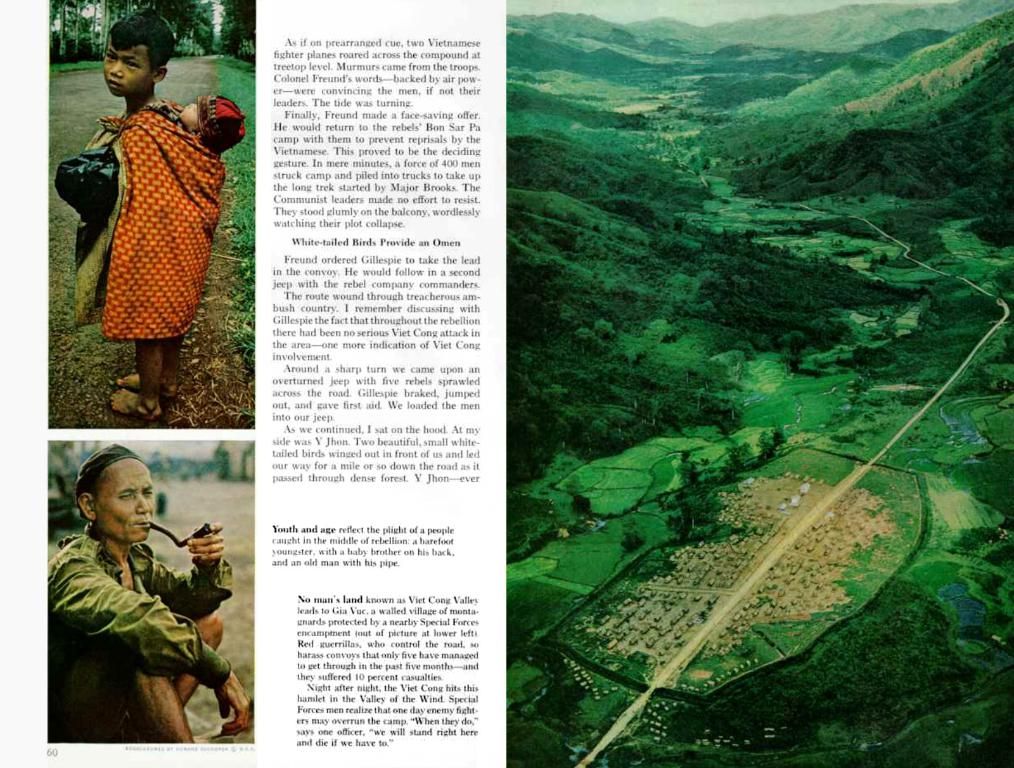

The recent boom in cost-effective, one-off PCB manufacturing has been a game-changer for electronic hobbyists over the past few decades. Few might still etch their own boards, but many have happily swapped their ferric chloride for a more modern approach. One such approach is PCB milling, a method that Tom Nixon has taken to the next level with his homemade mini CNC mill.

This mill operates like a regular XYZ mechanism, with belt drive for the X and Y and a lead screw for the Z axis. The sturdy frame is crafted from aluminum extrusion, with 3D printed parts like belt tensioners rounding out the design. The write-up offers a detailed walkthrough of the construction process, taking readers through each phase. The brain of the operation is a Creality 3D printer controller, although Nixon acknowledges it may not be the best fit for the task.

While Tom Nixon's mill is not the first PCB router we've seen, it certainly stands out as one of the more visually appealing ones. If you decide to make a PCB using this method, you might want to give it a professional-quality solder mask using a laser.

Solder mask application on DIY PCBs using a laser isn't quite as straightforward as some might think. Lasers are usually employed in PCB manufacturing for cutting stencils or for precision imaging in professional settings. Directly using a laser to apply solder mask, however, is not the norm. Here's a simplified guide on how to achieve a pro-level finish with some creative techniques:

Preparing the PCB Surface1. Clean the PCB: Ensure the PCB surface is free of dirt, oils, and other contaminants using isopropyl alcohol or a similar cleaning solution.2. Solder Mask Ink: Apply a UV-curable solder mask ink specifically designed for PCBs using a brush or spray.

Creating a Solder Mask StencilSince lasers are more commonly used for making stencils, you can create a stencil for applying solder mask ink:

- PCB Design: Utilize PCB design software to create Gerber files or similar formats that outline the areas where the solder mask should not be applied. Convert these files into a format suitable for laser cutting, such as PNG or vector files.

- Laser Cutting: Employ a laser cutter (e.g., CO2 laser) to cut out the stencil from a material like vinyl or even a metal sheet for a more durable option.

- Applying Solder Mask Ink: Place the stencil over the PCB and apply the solder mask ink using a brush or roller, making sure the ink doesn't spread beyond the stencil boundaries.

Curing the Solder Mask1. UV Light: Expose the applied ink to UV light to cure it, ensuring the light intensity and exposure time are appropriate for the ink type.

Final Touches1. Inspection and Cleaning: Inspect the PCB for any excess ink or defects, cleaning any unwanted ink with a solvent.2. Additional Coatings: Apply additional coatings as needed to protect or enhance the board's appearance.

While laser cutting stencils is a viable method, directly applying solder mask with a laser isn't a standard practice. Solder mask is typically applied using a separate process, such as screen printing or spraying, in professional settings. DIY projects may require more manual effort and creativity to achieve a professional finish.

For precision and reliability, professional PCB manufacturing often employs advanced techniques like laser direct imaging (LDI) for layer alignment and solder mask application. However, these techniques are typically beyond the reach of homemade projects.

- For a DIY PCB project, using a laser to create a solder mask stencil could be a useful technique before applying the solder mask ink, offering a professional-quality finish.

- In the realm of gadgets and technology, the integration of data-and-cloud-computing solutions is revolutionizing PCB milling, as advanced machinery like Tom Nixon's mini CNC mill is a testament to the possibilities that lie within data-driven technology.